Industrial cables, wires, and hoses play a critical role in powering and connecting machinery, systems, and infrastructure across sectors like oil and gas, metal processing, power generation, and manufacturing.

But in high-performance environments, these components face extreme threats: sustained heat, molten splash, abrasion, UV exposure, chemical corrosion, and mechanical stress. Protecting them is an operational necessity.

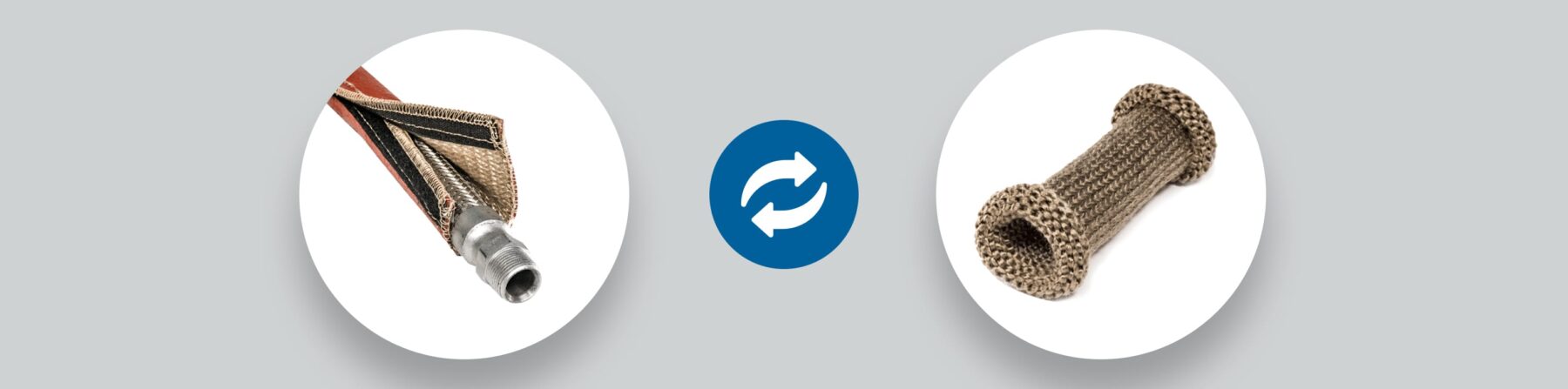

Thermal sleeving has long served as a protective barrier, but as industrial demands grow, the materials must change to keep up. Today, silicone sleeves and basalt sleeves have emerged as two of the most advanced solutions for durable, reliable wire and hose protection. Each offers unique benefits, and choosing the right one can mean the difference between costly downtime and continued productivity.

Discover how silicone and basalt sleeves have become the perfect solves for extreme heat and abrasion challenges in industrial spaces.

The Industrial Conditions Demanding More from Sleeving

Industrial settings can push every component to its limits. In its Technical Manual on heat hazards, OSHA highlights high-temperature exposure as a common risk in metal processing, refining, and energy sectors—not just for workers, but for the systems that support them.1

Heat, abrasion, and contaminants can degrade wire insulation, rupture hoses, and compromise cable integrity.

That’s where advanced sleeving solutions like silicone and basalt come in. Both are engineered to protect against intense thermal and mechanical stress while maintaining flexibility and ease of installation in real-world industrial environments.

Silco® Sleeves: Premium Protection with Silicone-Coated Fiberglass

Davlyn Group’s Silco® Sleeves are constructed from braided fiberglass yarns coated with a thick layer of premium-grade silicone rubber. This composite structure delivers exceptional thermal and flame protection with a clean, professional finish.

Key Specifications:

- Continuous Temperature Resistance: Up to 500°F (260°C)

- Molten Splash Resistance: Up to 2,200°F (1,200°C)

- Flame Resistance: Excellent for weld spatter, molten splash, and direct flame

- Environmental Resistance: UV, moisture, and abrasion resistant

- Flexibility: High expansion for easy routing around couplings and tight bends

Silco® Sleeves are available in multiple constructions, including Standard Firesleeve and Firesleeve with Hook & Loop, which is designed for easy retrofitting without disconnecting hoses.

These sleeves are commonly used in steel mills, welding and cutting operations, hydraulic hose protection, and engine compartments where exposure to flame or molten splash is frequent. Their ability to conform around fittings and endure heavy-duty use makes them a top choice for maintenance-heavy settings.

Basalt Sleeves: Natural Fiber & Engineered Strength

Basalt Sleeves are woven or knitted from continuous basalt fibers derived from volcanic rock. This uncoated, high-performance material delivers excellent resistance to heat, abrasion, and environmental stress, making it ideal for demanding industrial settings. With no added coatings or fillers, basalt sleeves offer natural flame resistance while meeting the mechanical durability required in high-wear environments.

Key Specifications:

- Continuous Temperature Resistance: Up to 1382°F (750°C)

- Abrasion Resistance: Higher than fiberglass; suited for rugged conditions

- Electrical & Chemical Properties: Non-conductive; UV and chemical resistant

- Sustainability: Non-toxic, eco-friendly, and free of asbestos or ceramic fibers

- Construction Options: Knitted Basalt Sleeves for more flexible routing around irregular shapes and Braided Basalt Sleeves with tighter weave for enhanced mechanical protection

Basalt sleeves are a smart fit for engine and exhaust insulation, cable protection in high-temperature zones, and OEM builds where sustainability and long-term performance are critical. Their high thermal endurance and rugged structure make them ideal for prolonged exposure to radiant heat.

Thanks to their flexibility, especially in knitted constructions, basalt sleeves are also commonly used to protect bellows and expansion joints, where materials must withstand movement and vibration without sacrificing thermal integrity.

Silicone vs. Basalt: Which Should You Choose?

Silicone and basalt sleeves bring powerful performance to demanding industrial environments, but their strengths lend themselves to slightly different applications. While both are flame resistant and designed to shield wires, hoses, and cables from extreme temperatures and wear, your choice may ultimately depend on the specific thermal, mechanical, and installation needs of your operation.

Silco® silicone sleeves are particularly well-suited for applications that experience sudden bursts of extreme heat, such as weld spatter or molten splash. Thanks to their silicone-coated fiberglass construction, they offer strong resistance to moisture, UV exposure, and mechanical stress. They’re also highly flexible and expandable, making them ideal for routing around tight bends and retrofitting existing systems.

Choose Silicone if:

- You need protection from intermittent flame or molten metal splash

- You want a coated sleeve that withstands moisture and UV exposure

- You value flexibility and ease of installation (especially for retrofits using hook-and-loop closures)

Basalt sleeves, on the other hand, are ideal for environments that maintain high temperatures for extended periods. Their tightly woven or knitted basalt fiber construction offers natural resistance to heat, abrasion, and chemicals without the need for coatings. While slightly less flexible than Silco® silicone, they offer greater long-term durability and strength in abrasive or high-contact environments.

Choose Basalt if:

- Your application involves continuous exposure to high temperatures

- You need exceptional abrasion resistance in rugged conditions

- You prefer a sustainable, uncoated solution with strong environmental resilience

Why Engineers Trust Davlyn Group

For decades, Davlyn Group has helped power industrial progress with advanced thermal protection solutions. With deep expertise in both coated and uncoated materials, we offer:

- Diverse sleeving constructions to fit specific applications

- OEM-grade quality control and US-based manufacturing

- Application engineering support to help spec the right product

- Quick-turn sampling and responsive customer service

Whether you’re outfitting new systems or improving existing equipment, Davlyn Group sleeves are engineered to deliver long-term protection and performance in the world’s toughest environments.

Prioritizing Protection, Performance & Precision

Wire, hose, and cable failures in high-heat zones can lead to downtime, safety risks, and expensive repairs. Silco® silicone and basalt sleeves offer two high-performance paths to protection suited to different priorities, from flexibility and retrofit convenience to maximum abrasion resistance and thermal longevity.

Choosing the right sleeving solution is more than a material decision. It’s a decision about uptime, safety, and operational confidence.

Ready to specify a better sleeve? Contact us for a recommendation based on your specific application.

Sources: